A well-chosen ramp changes lives—learn how to assess and prescribe them effectively.

As an Occupational Therapist, an important part of your role may be to assess for and prescribe ramps.

Through completion of a comprehensive Occupational Therapy functional assessment, barriers to performance can be identified and prescription of home modifications, such as ramps, can be recommended.

This guide will provide you with almost everything you need to know about ramps including the different types and when they are appropriate, how to assess them and general standards to be aware of, and what documentation and diagrams you might require.

We say almost because:

- A comprehensive Occupational Therapy functional assessment is critical to ensuring correct ramp prescription;

- There is always more to learn;

The gradient should be proportional to the total height of the ramp and should be guided by the relevant building standards. See our section on gradients for more information; - Ramps should be at least 36 inches wide, measured between the internal edge of the handrails;

- All outdoor ramps with a rise of 6 inches or more are required to have handrails on both sides;

- Landings are required at the top and bottom of each ramp run, and wherever the ramp changes direction;

- One landing is also required for every 30 feet of continuous ramp (or every 30 inches of vertical rise);

- Landings must be level and clear to prevent an accumulation of water, measuring at least 60 inches wide and 60 inches long;

- Any handrails, vertical posts, edge protections, and other ramp components should not fall within the 60 x 60 landing space;

- Landing changes in level should not exceed a gradient of 1:48.

When assessing and prescribing ramps there are important things to consider including:

- Types of ramp

- Ramp materials and finish

- Landings

- Handrails

- Other considerations

1. Types of Ramps

Within building standards, there are often references to different types of ramps.

We describe ramps in accordance with the overall height. For example, a threshold ramp has a maximum height of 3 inches. The height of a ramp is also referred to as the ‘rise’.

Threshold ramp

A threshold ramp has a maximum rise of 3 inches; no maximum length requirements; and a maximum gradient of 1:12.

A threshold ramp and a standard disability ramp serve the same purpose—providing accessibility for individuals with mobility challenges—but they differ in design and use cases.

The purpose of threshold ramps is to bridge a small height difference, such as the transition from one surface to another (e.g., doorways). They can also include wings, as pictured below.

Step ramp

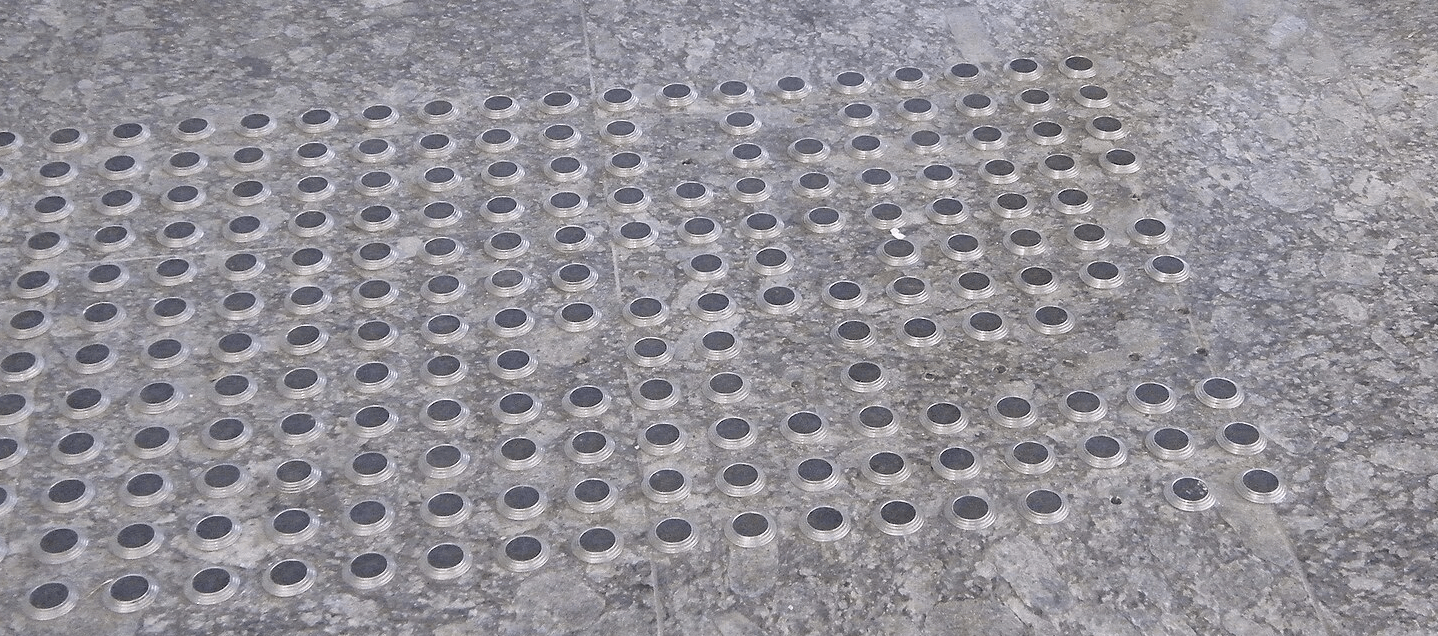

A step ramp has a maximum rise of 30 inches, no limitations on the maximum length, and a maximum gradient of 1:12 for running slope and 1:48 for cross slope. The ramp should have a slip resistant surface.

When positioned at a doorway, the ramp landing can overlap slightly with the overall clearance for the door. However, it is recommended to position the arc of the door swing outside of the ramp landing itself for maximal safety.

Edge protection is used to keep crutch tips and wheelchair casters on the ramp surface and can be provided by barriers, extended surfaces, or curbs.

Curb ramp

A ramp located within or attached to a curb is often referred to as a curb ramp.

These types of ramps are typically seen on public streets where there is a change in height greater than ½ inch. A curb ramp must have a width of 36 inches (not inclusive of handrails, flared sides, indentations, or other features); maximum rise of 30 inches; and a maximum gradient of 1:12. There are no restrictions on the length of a curb ramp. Hhand rails are required if the curb ramp has a rise greater than 6 inches.

When curb ramps are placed in spots with limited space, alterations to the gradient may be made. For example, a gradient of 1:10 with maximum rise of 6 inches is permissible, as is a maximum gradient of 1:8 with maximum rise of 3 inches.

Ramp

A ramp can be defined as an inclined surface between two landings with a gradient steeper than 1:20. The length of the ramp is determined by the height of the rise with reference to the gradient required.

2. Ramp Material and Finish

While ramps are not required to have a slip resistant finish, they are often recommended to ensure the safety of those using the ramp. When considering the prescription of the ramp material, some important things to consider include:

- Location

- Budget

- Longevity requirements

- Maintenance requirements

Typically, the following materials are used for ramps:

Wood

Wood is generally less expensive and many people prefer the aesthetics of a wooden ramp as it looks more homely compared to concrete and metal which can look more industrial.

Wood, however, must be sealed and requires greater maintenance, such as yearly staining, to prolong its lifespan.

Aluminium

Modular or prefabricated ramps are often made out of aluminium and can be used as permanent options for large ramps as an alternative to wood.

They can also be great temporary or portable options and will typically last a long time, although are subject to corrosion in certain environments.

It is important to note that aluminium can hold heat and be reflective which can impact functionality.

Concrete

Concrete ramps are very low maintenance, however, can be quite expensive to install, are a permanent structure, and are prone to breaking / cracking if the base is not appropriately prepared for pouring.

Concrete ramps are generally suitable for areas with a high fire risk rating or high altitude.

Steel

Steel ramps typically carry substantial costs and therefore, are not generally seen in residential homes unless required for specific reasons.

A stainless steel ramp might be used in a coastal location to prevent rusting, or a high fire risk rating area.

Rubber

Rubber ramps have become very popular for indoor and outdoor threshold ramps due to being hard wearing, semi-permanent, and cost-effective for smaller ramps.

For larger ramps, rubber can become expensive and heavy.

3. Ramp Landings

Ramp landings are important and should be installed at the top and bottom of each ramp run, whenever there is a change in direction, and when the ramp meets a door or entry point. Landings must be level and clear to prevent an accumulation of water and ensure safety for users.

One ramp landing should be installed after every 30 feet of ramp run with a gradient of no more than 1:48.

According to the U.S. ADA standards, a ramp landing must:

- Be a minimum of 60 inches long;

- Be a minimum of 60 inches wide;

- Have grade breaks perpendicular to the direction of the ramp run, which helps keep the ramp level and avoids cross-slope problems;

- If there is a perpendicular access route to the curb ramp, the top landing should have a maximum gradient of 1:48;

- If there is a parallel access route to the curb ramp, the top landing should have a maximum gradient of 1:20.

Ramp landing measurements can vary significantly when involving a doorway according to the approach direction, door size, and direction of door opening.

There are separate specifications for curb ramp landings:

- Curb ramp top landings should be at least 36 inches long and 36 inches wide to allow someone to move on and off the ramp without the need to utilize the side flares;

- If the curb ramp has side flares, they must have a maximum gradient of 1:10;

- If there is no space for a top landing, side flares are required and cannot slope more than 1:12;

- If there is no space for a top landing and there are also no side flares, a parallel curb ramp is a viable alternative.

All factors that may influence the circulation space required on the landing should be considered, for example, bariatric or large equipment.

4. Rails / Barriers

Please refer to our rails guide for in-depth information about handrails and grab rails. There are several important handrail considerations however that are specific to ramps.

A barrier is required for any ramp where the ramp or landing level has a rise greater than 6 inches. Barriers should be mounted 34 to 38 inches above the surface of the ramp and 36 inches apart from one another. If a guardrail is present, it should be at least 42 inches from the walking surface. Barriers can include:

- Handrail with a curb rail (this is most common);

- Balustrades;

- Glass;

- Horizontal wire systems with a curb rail.

Tip: You can read more about balustrades and barriers in our Occupational Therapist’s Guide to Stairs.

The most common usecase is residential settings, such as doorways.

Other considerations

Head clearance is an important consideration when prescribing a ramp.

There should be a minimum of 80 inches head clearance above the ramp surface and landings to ensure the ramp can be used safely. You may need to consider lighting, roofing, window sills, etc.

Documentation and Diagrams

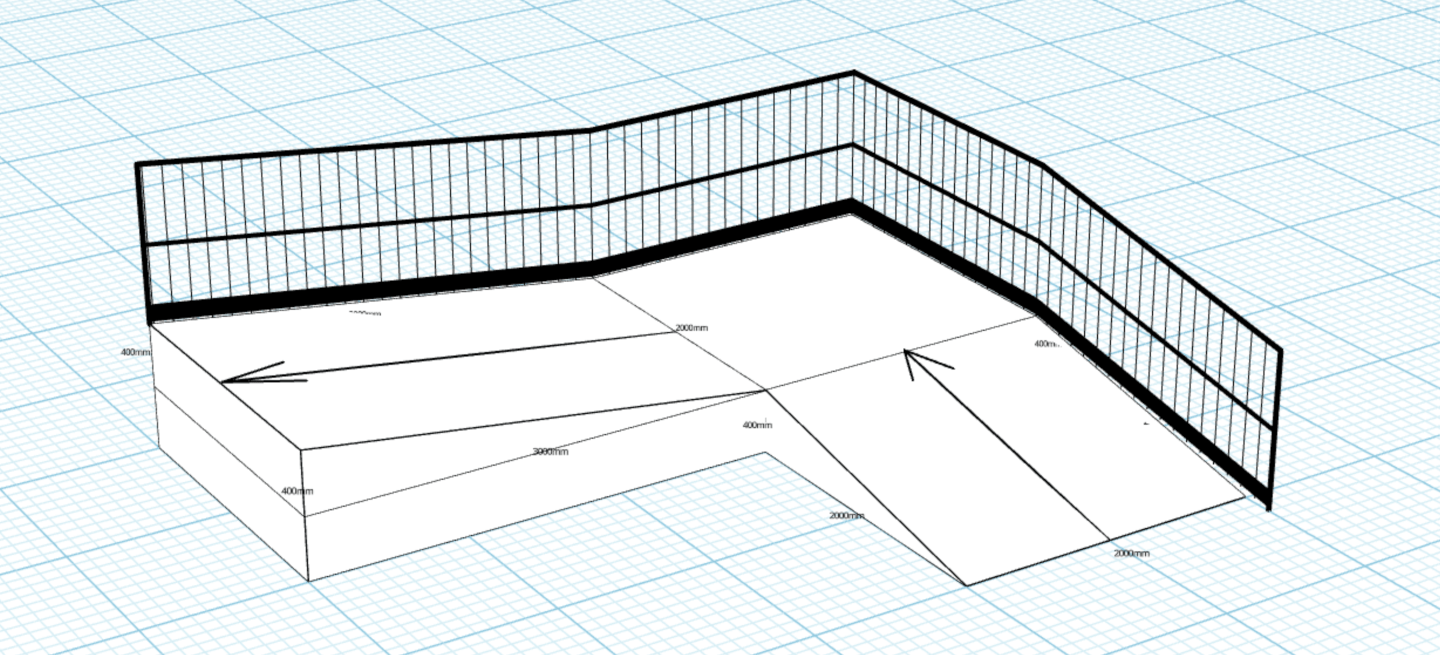

Once you have completed a comprehensive functional assessment to determine the most appropriate ramp modifications for your client, you will need to communicate this to the builder or tradesperson you are requesting to complete the works.

One way to do this is by writing a scope of works (also referred to as SOW) that documents the works that you are recommending and includes scale diagrams of the proposed modifications.

A scope of works will typically include:

- Photos of the space to be modified;

- A detailed description of the proposed modifications;

- Measurements of the existing space and proposed modifications; and

- Diagrams of the proposed modifications.

It is a good idea to include a clause for deviation in your scope of works advising the builder or tradesperson to contact the OT, if they are unable to complete the installation as outlined.

Design Ramps with Moddy – Free 7 Day Trial

Occupational Therapist’s use a variety of software to support the design process of minor and major home modifications. The diagrams can range from simple to complex and need to clearly show the proposed works in order to achieve the best possible outcome for our clients.

Here at Moddy, we are passionate about helping Occupational Therapists design professional ramp modifications.

- Our software supports comprehensive ramp modification diagrams.

- Our product was designed in conjunction with practising Occupational Therapists.

- We allow exportation of 2D/3D diagrams for our users to attach to their home modification reports.

- Our product is suitable for OTs world-wide.

To get started as an individual or organisation, please click here.

Start free 7 day trialGlossary

Circulation space: Circulation space refers to the space that is used for people to circulate such as corridors, entrances, stairs, landings and areas that connect two spaces.

Door leaf: The part of the door that swings open and closed, sitting inside the doorframe when the door is closed.

Gradient: The degree of inclination.

Curb Rail: A rail that is placed above floor height and acts as a barrier to prevent people or objects from falling from a ramp.

Rise / riser: The vertical section between the treads of a staircase or the height of a step.

Scope of Works (SOW): A document that contains a description of the work to be performed.

Slip resistant surface: A surface that has sufficient friction to enable an individual to traverse that surface without an unreasonable risk of slipping.

Reference List

U.S. Access Board. (2024). Guide to the ADA Accessibility Standards. Retrieved from https://www.access-board.gov/ada/guides/chapter-4-ramps-and-curb-ramps/